Digital Surfacing does not have these limitations. With digital surfacing, labs can produce unlimited shapes and exceptional accuracy (0.01D) on one or two surfaces of the lens to achieve the intended design. In digital surfacing, surface designs are stored as computer files and can be modified as needed based on patient and frame data when the actual lens is created. The computer translates the design exactly to either lens surface and controls the lathe that creates that design. Lenses can be created in infinite numbers of designs. As a result, of the digital surfacing process, the optician can deliver to the patient a better visual solution, based on personal measurements, physiological data and in almost any frame chosen.

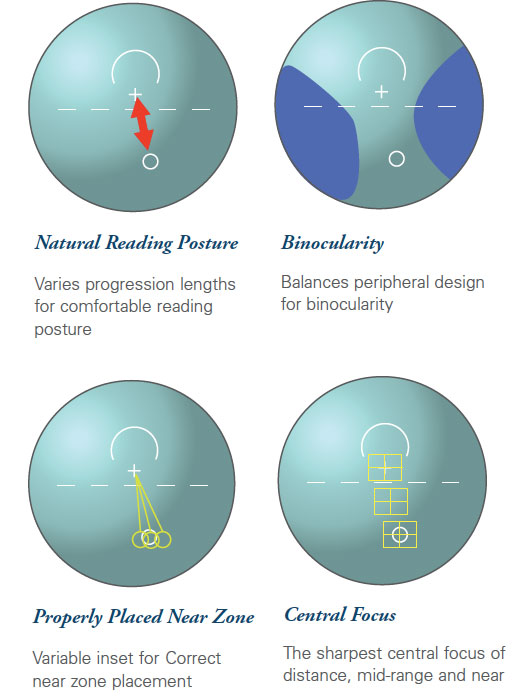

ADJUSTABLE DESIGN PARAMETERS