Reprinted from 2020 CE course

Patient Benefits with Trivex© lens material

FRAME CHOICE

Frame choice also drives material choice. Usually the patient will select their frames first and then the lenses. This can present a problem with some lens materials. Consider the combination of a plus lens and a grooved semi-rimless frame. Lenses made from CR-39 material flake or chip at the thinnest corner. Oftentimes, patients will return a pair of rimless glasses because of star cracks around the drilled holes or flaking at the edges.

Patient Benefit-Frame Choice Freedom

Lenses that retain their looks and safety regardless of frame style allow patients to select the frame of their choice knowing that the lenses will not be affected. By selecting a lens material that doesn’t flake or crack, opticians can feel confident that no matter the frame choice of the patient, the lenses will be suitable for the frame. Trivex material is unique in that it has extremely high strength and virtually no notch sensitivity. This means that the lenses won’t develop edge flakes or chips, and when used for drilled rimless, won’t star crack. This is particularly important in drilled polarized lenses. Polarization efficiency is affected by compression at the drill points. Choosing Trivex material solves many problems before they start by reducing breakage and remakes.

PATIENT TARGET

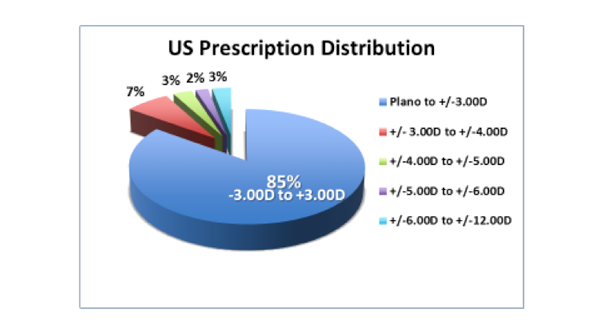

Eighty-five percent of the U.S. population that requires vision correction is within the range of -3 to +3 diopters, which means the majority of patients might not require a high-index material to achieve a thin lens. Trivex material will produce an equivalent or comparably thin lens for these prescriptions while also providing the patient with a more robust combination of lens attributes – optical clarity, lightweight comfort, impact resistance and UV protection.

TRIVEX MATERIAL FOR KIDS

Kids need sharp, precise vision for all they do. Their active and unpredictable lives also demand spectacles that provide the best strength and protection.

It’s estimated that 80 percent of what children learn in their first 12 years comes through their eyes. However, children’s eyes are underdeveloped. In fact, the crystalline lens of a child’s eye is virtually transparent and offers very little protection for the retina. The eyes of a child under the age of 10, transmit over 75 percent of UV radiation compared with 10 percent in adults, ages 25 years and older.

Here are five scripts you can use to highlight the importance of quality lenses for kids:

“We only use lenses made with Trivex material that provide extreme protection from UV radiation and are impact resistant while delivering the best in clear vision for your child.”

“Because children rely on their vision for learning, it is important that they have the most durable, non-glare lenses made with Trivex material.“

“Non-glare lenses can eliminate headaches and tired eyes caused from white boards, computers and classroom lighting.”

"In addition, since children spend more time outdoors, they are exposed to more glare and harmful UV rays.”

“I recommend lenses that absorb 100 percent of the harmful UV rays. They are also available in photochromic lenses that change tint when your child goes outdoors and then changes back to clear when they come back inside.”

WHAT TO SAY

When making a lens recommendation, include the patient benefits of the lens along with the lens attributes. The more “true-to-life” the description, the more it will resonate with the patient. Again from Vision Watch, you are in control of the lens’ attributes because consumers report that their decisions are ECP-driven. Almost a third report that their most important reason for purchasing is their ECP’s recommendation.

Suggesting a change to Trivex material as a replacement for CR-39 material might sound like this:

- I’m recommending lenses made from Trivex material because it delivers crisp, clear vision with exceptional optical performance.

- Your lenses will be ultra-lightweight, providing added comfort since Trivex material is one of the lightest lens materials available.

- This material automatically provides 100 percent UV protection and is unsurpassed in impact resistance and durability, meaning your eyes will always be protected.

Part Four and final part of this educational series focused on Trivex lens material gives practical advice for usage and prescribing Trivex lenses.

- Both CR-39 monomer and Trivex material are manufactured by PPG Industries.

Mark Mattison-Shupnick, ABOM, is currently director of education for Jobson Medical Information LLC, has more than 40 years of experience as an optician, was senior staff member of SOLA International and is a frequent lecturer and trainer.