This is a reprint of a 2020 CE, part three of three with kind permission from 2020 CE Study Center

AIM FOR THE BULLSEYE

With many variables to sort through in investigating a vision complaint, anything that could help to reduce the pool of possible suspects should be welcomed with open arms.

Luckily, eye care professionals not only recognize the importance of this area, they are highly skilled in it as well. The art of taking measurements, from PDs to Seg heights, ECPs are fiercely proud of the pains they take everyday to ensure the traditional measurements needed for eyewear are as precise and accurate as they can be. That's why it comes as a surprise for lens manufacturers to discover that ECP's often under appreciate all the inherent benefits of taking vertex distance, Pantoscopic tilt and wrap angle measurements in every pair of eyewear sold.

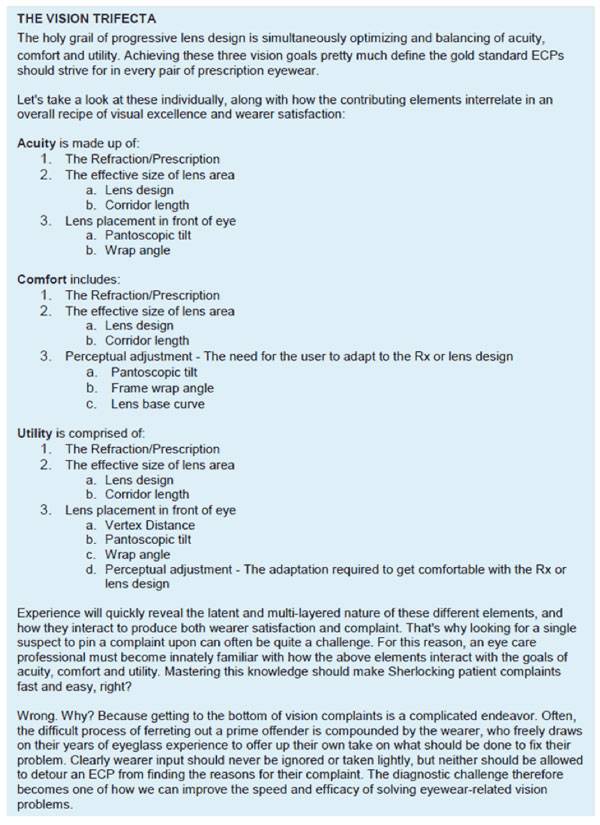

At the front lines of optical — at the dispensing desk — the one given in designing of a pair of eyewear is the Rx. In the recipe of eyewear satisfaction, this is the bedrock upon which all else is built. Given this, it is amazing how many pairs of eyewear, even when their prescriptions have been accurately verified, come back in the hands of the wearer, accompanied by some complaint related to acuity, comfort or utility. The reasons for this should now be clear: Lens designers have had to make many assumptions about how lenses would be positioned and aligned in front of the patient's eyes. And it is this lack of knowledge of the actual position of wear that often moves a pair of eyewear off the bulls eye of perfect to the outer border region between acceptable and unacceptable. By taking and supplying position of wear measurements in the lens ordering process, ECPs obtain the ability to move that pair of eyewear much closer to the bulls eye of perfect, the area the vision trifecta described above calls home.

THE PHOROPTER, WELCOME TO FLATLAND

The main tool today for refining the all-important subjective refraction is the Phoropter. It consists of small diameter lenses that are Flat in curve, positioned perpendicular to the floor at zero pantoscopic tilt, positioned in a flat plane, at zero wrap angle and positioned a fixed distance from the eye, approximately 12mm-14mm.

But outside the exam room, lenses for eyeglasses are larger, requiring a curved profile for better peripheral vision. At the same time, the lens' actual position in front of the eye i.e., the position of wear, differs as well from the frames that are encountered in the exam room. For example, there is Pantoscopic angle; eyewires are tilted inward, toward the cheeks approximately 5-8 degrees. There is also a wrap angle. The frame is wrapped a modest degree, approximately 5 to 7 degrees, around toward the temple. This is done to improve cosmetics and reduce off axis aberrations, including skew or geometric distortion.

These profile and positional differences are the basic elements that Corrected Curve theory and Martin's Rule of Tilt attempt to address to maximize peripheral acuity in single vision lenses. However, in progressives the situation becomes more complicated. Because of the need to blend the progressive corridor into the adjoining lens topography, maintaining good acuity in the peripheral temporal areas becomes far more important. The inferior area also rises in priority as the presbyopic eye relies this region for reading. These two considerations mandate that the precise position of the lenses be seen from a more global perspective in order to deliver fully on the potential of customized free form optimization.

In traditional progressives, entry of individual position of wear parameters into the design process is not possible. Engineers therefore relied on averages gleaned from accumulated fitting data. The advent of using POW values in real-time lens optimization represents an important milestone in the evolution of progressive lenses.

THE MORE THE MERRIER

Faced with the daily task of integrating the above considerations in every pair of progressive glasses can appear daunting to ECPs, and it is easy to see why many continue to rely upon what's worked "good enough" in the past. But continuing to rely on a traditional design, fitted with default position of wear values, a simple PD, height and boxed frame dimensions is quite a bit away from the state of the art.

Further, avoiding the use of customized progressives is not only amounts to leaving "money on the table," it is, more importantly, no longer what today's savvy, online-informed consumer expects when they pay the higher prices asked by their local optical store.

CONCLUSION

The message going forward is clear: Premium prices must be clearly associated with premium products, service, and expertise. And that expertise is only clearly evident when eyecare professionals take the time to measure, calculate and explain why all those fancy POW measurements they didn't take before have become important today. When it comes to the real details of vertex distance, Pantoscopic tilt and wrap angle, the more measurements you take, the merrier your clients will be about the terrific acuity, utility and comfort of customized, free-form progressive lenses.

Barry Santini, ABOM, graduated from New York Technical College in 1975 with an AAS in Ophthalmic Dispensing. He is a New York State licensed optician with contact lens certification, is ABO certified and was awarded an ABO Master in 1994. As sales manager for Tele Vue Optics from 1987 to 2003, Santini developed his knowledge of precision optics and has been an owner of Long Island Opticians in Seaford N.Y. from 1996 to present. In addition, Santini is an amatuer astronomer and lecturer and plays bass trombone in the Brooklyn Symphony.