The fourth most abundant metallic element in the earth’s crust, titanium is found in ilmenite and rutile ores mined largely in Australia and South Africa. Titanium has unique characteristics, making it the metal of choice for applications as diverse as aerospace, industry, chemical processing, marine, medical, sporting and consumer goods such as cosmetics and eyewear. Because of its high strength to weight ratio, titanium’s original use was in the military aerospace industry. Other properties that make titanium the metal of choice is its unique look, the fact that it is nonmagnetic, has the ability to maintain strength at high temperatures, and it has a relatively high melting point. Titanium is corrosion-resistant, biocompatible, flexible and exhibits good thermal conductivity.

And here’s something really unique: When exposed to oxygen, titanium creates a layer of a ceramic-like oxide film, which is the reason it resists corrosion. Even better, if it gets scratched, as long as it is exposed to oxygen, the scratch will heal itself with the oxide film! Titanium is nontoxic, even in large doses, making it biocompatible and useful for implanted medical devices and hypoallergenic eyewear. In fact, most people ingest an estimated 0.8 milligrams a day that passes through our systems without absorption and without effect.

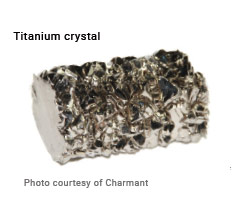

In addition to all of those characteristics, titanium is naturally beautiful. In its pure form, it is silvery with bluish highlights, depending on the ore it’s derived from and can be polished to a high luster. Titanium won’t discolor, and its use in jewelry has become a popular alternative to more expensive metals like gold and platinum. The totality of those attributes make titanium ideal for eyewear, and Charmant leads the way in that application.

Charmant began working with titanium to produce eyewear in 1982 and introduced the Pure Titanium collection in 1983. In its commitment to quality, Charmant only calls materials made with 100 percent titanium Pure Titanium, exceeding The Vision Council guidelines for frames to be certified 100 percent titanium. Frames are ultra-lightweight, nickel allergy free and exhibit superior corrosion resistance. This coupled with unsurpassed quality, style and durability deliver a collection that is a step above the competition. Constantly researching new materials and techniques, Charmant introduced a lighter and stronger material, Beta Titanium, in 1990. Beta Titanium is an alloy consisting of titanium, vanadium and aluminum. It is stronger than pure titanium, but just as lightweight and corrosion resistant. Due to its elastic properties, even a thinly designed Beta Titanium frame retains its strength, allowing for more delicate looking frame designs.

Continuing its focus on quality titanium eyewear, in 2009, Charmant developed a proprietary new material, Excellence Titan, as part of an eight year joint venture project with Tohoku University. Extremely lightweight and with a high-flexibility memory function, it is the most comfortable titanium alloy material that the Charmant Group offers today and is the feature material in Charmant’s LineArt frame collection. Another innovation that gave birth to the LineArt collection was the development of microlaser welding technology to enable the welding of small parts. A result of five years of intensive research and thorough testing, microlaser welding allows strong welding to even the smallest parts of the frame without compromising the material’s integrity. Normally, brazing was used to join metal pieces during the eyewear fabrication process. However, the high heat levels generated during brazing tended to weaken the base material and could cause structural changes in the metal resulting in the parts detaching. Micro laser welding offers limitless design options ensuring frames that are both aesthetic and comfortable with seamless joints. This welding technique can join extremely fine parts directly, using no medium material that could cause possible breakage. It is an ideal solution in eyewear manufacturing that requires highly precise processing capability. It gives a high-strength welding and beautiful finish to fine eyewear.

As can be seen in their eyewear lines of style, comfort and durability, Charmant recognized not only the natural beauty of titanium but its other attributes making it the material of choice for eyewear. Learn more about titanium and the features and benefits of titanium frames with our CE, “The Many Material Benefits of Titanium Frames” at 2020mag.com/ce.