Reprint of CE with permission

INTRODUCTION

For every power, there is an ideal base curve. The industry, for various reasons, doesn't strictly adhere to this principle, but it's crucial to note that base curves are still very important. As it turns out, good optics are more closely related to base curve than typically thought. With that recognition, Younger Optics released a new lens technology called Camber, a new and unique digital progressive lens solution that uses a variable base curve on its front surface to widen the clear field of view from far to near. This course teaches how Camber combines the traditional optics of base curve choice with modern digital processing.

WHY HAS BASE CURVE CHOICE DOMINATED LENS SELECTION AND PROCESSING?

As you know, the combination of front and back curve provides lens power. It doesn't matter what curves are used to make a -3.00D lens for central power as long as the result is -3.00D. However, the curves chosen do affect the sharpness of the off-center areas. Because of this, front curve choice (base curve) has been a guiding principle for more than 200 years in the quest for better ophthalmic lenses.

For every lens power, there are actually two base curves that offer clear vision off-center. In 1804, Wollaston developed an elliptically curved line graph matching each lens power to an "ideal" base curve, which is free from oblique astigmatism (peripheral blur). However, these early lenses were very steep, with base curves of almost up to 20D; therefore, a more practical solution was sought. In 1898, Ostwalt discovered that Wollaston's elliptically curved line graph had a lower half (Fig. 1). This meant that each lens power had a second ideal base curve. Though both base curves reduced peripheral blur to almost zero, Ostwalt's base curves were adopted as standard because they were flatter, more practical and better looking than Wollaston's. Originally, each and every lens power had a different recommended front lens curve. The glass lens manufacturers of the time found this to be unmanageable and way too costly. Therefore, they reduced the number of available base curves and began to produce a range of prescriptions from each one.

This simplified Ostwalt system is the basis for the modern base curves that are still used for most single vision lenses and traditional progressives. Over time, industry standards have shifted toward flatter curves than those initially suggested by Ostwalt, in order to improve eyewear cosmetics. In times when style dictates small frames, this shift does not result in noticeable oblique astigmatism, because smaller frames mean a shorter distance from center to edge. However, when frames are larger, the demand for flatter, more attractive lenses often leads to sacrifices of optical quality.

CAN A SINGLE VISION LENS BLANK SATISFY THE BASE CURVES REQUIRED FOR THE DIFFERING LENS POWERS IN A PROGRESSIVE LENS?

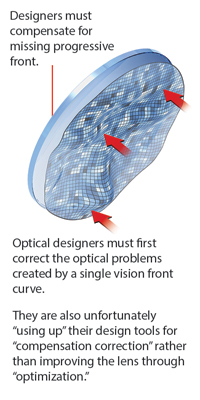

As explained, historically, for every power there is a "correct and best" base curve. Move away from the ideal base curve and the ability to control peripheral blur decreases. That reduces the clear field of view. If we're making a backside progressive lens, and we choose a SV lens blank whose base curve corrects for distance power, that curve is not the right one required for near vision, a power of less minus or more plus (Fig. 2). In most cases, more than one base curve would actually be required for correct optics.

Historically, traditional fixed front surface progressives have been widely successful. Traditional progressives are able to provide accurate optical correction because there is a varying curve inherent within the molded front surface design. In contrast, modern backside digital technology applies the progressive design to the backside of a spherical lens blank. This creates an intrinsic compromise, because the single base curve can correlate to the distance power or the near power, but not both at once. This usually means that the near zone power is not appropriately matched to its ideal base curve. Because the near zone is viewed obliquely, this mismatch is of greater consequence.

Optical designers (Fig. 3) must first correct the optical problems created by a single vision front curve. That makes sense and is an advantage of digital processing. However, the design tools are also unfortunately using up their compensation correction for a less than ideal base curve rather than improving the lens through optimization.

ISN'T ALL DIGITAL TECHNOLOGY/FREE-FORM BETTER?

Do you agree with the statement, "Free-form, i.e., digitally-compensated lenses produce more satisfied patients"? I know most do agree, because when I ask that question to those in attendance at my classes, almost all of them selling digital lenses say they agree. However, as many have experienced, results vary depending on how judiciously the free-form processes are applied. In fact, that range of free-form processing capability is what provides a good, better and best choice of lenses. While all digital lenses use compensation to improve peripheral vision, keep in mind that the more compensation is required, the less optimization is possible. That is to say, reducing the need to compensate expands the lens' personalization and optimization opportunities.

In cases where an overly flat base curve is chosen (for example, a low plus Rx in a large, flat retro frame), or an overly steep lens is chosen (for example, a -4.00D Rx in an 8-base sport frame), free-form compensation may be applied to improve peripheral vision. However, because the base curve of the chosen blank is not ideal for the power of the lens, more compensation is required, sometimes more than possible. Maintaining the "ideal" base curve reduces compensation requirements.

A NEW METHOD TO DELIVER VARIABLE BASE CURVES: CAMBER TECHNOLOGY

New Camber technology combines complex curves on both lens surfaces. The continuously changing, special front surface uses more traditional, flatter curves for distance and steeper curves for near, thereby providing the optically correct base curve throughout the lens.

Please look for Part Two of this reprinted CE titled IMPROVING FREE-FORM LENSES WITH VARIABLE BASE CURVES AND DIGITAL INDIVIDUALIZATION

Product Spotlight: Camber Technology—A Unique Patented Variable Base Curve Digital Progressive.

Mark Mattison-Shupnick, ABOM, is currently director of education for Jobson Medical Information LLC, has more than 40 years of experience as an optician, was senior staff member of SOLA International and is a frequent lecturer and trainer.