By Barry Santini

Eyecare professionals have long held the belief that accurate measurements are essential for achieving both success and satisfied customers in the fabrication and placement of ophthalmic lenses. In the 13th century, the Venetian Guild of Crystal workers early on recognized this and secreted the tools, processes and knowledge of the art of lens making from outside prying eyes. This set a tone, and for the next 700 years, precision in spectacle measuring and making has forever after been held in the highest regard.

But at the dawn of the 21st century, the arrival of online delivery of prescription eyewear has many eyecare professionals reconsidering exactly how much measurement accuracy is necessary to deliver a pair of satisfactory eyewear. Is there a tangible and communicable value difference between striving for absolute excellence versus settling for “good enough” that today’s consumer is willing to pay for? To answer this question, let’s take a dive into the history of measurement and standards technology, and then go on to appreciate all the different powers that lie in the various metrics eyecare professionals use every day with eyeglasses. Finally, we’ll tackle the tough question of how much in-person assistance is actually needed to deliver eyewear that consumers recognize as good value in an age defined by rapid technological advancement.

THE IMPORTANCE OF METRICS

For early man, learning how to measure time in order to prepare for planting and harvests led them to focus on the parallax and transits of stars and by doing so, the science of astronomy was born. Over the ages, we’ve come to recognize that measurement values should always possess the following four qualities:

- Stability over time

- Uniformity independent of location

- Repeatability

- Easy accessibility

THE POWER OF METRICS

PD and height, that’s where it all begins when making most eyewear. And for the overwhelming majority of eyeglasses, PD is also where the measuring ends in a typical SV pair. Why? Probably because there aren’t a lot of complaints traceable to not paying attention to pupil height. But is a “lack of verbal complaint” a reliable metric for eyewear satisfaction? Many ECPs think so and therein lies the seeds for why online eyewear, which clearly lacks the intimacy of face-to-face, hands-on measurements, is found to be an increasingly satisfactory choice by the eyeglass buying consumer.

THE POWER OF THE PD

When opticians start the process of troubleshooting issues in a problematic pair of single vision glasses, among the first suspects they triage is the PD, i.e., “Be sure to check if the PD is off.” But exactly what does this mean? Actually, in technical terms, nothing, unless you first convert the found PD error to prismatic terms for tolerance analysis. So the whole idea that the “PD is off” is never about exactly where the optical center, or “OC,” is horizontally. Rather, it’s about whether the resulting prismatic error is either compounding a latent binocular vision issue or simply represents an adaptation issue affecting wearer comfort. This latter situation is encountered when the wearer is transitioning from a different or incorrectly made pair.

THE POWER OF THE OC

The optical center position, or “OC height,” is an often overlooked measurement in most eyewear unless the Rx is of significant power. In prescriptions over 3 diopters, most ECPs feel that the “purity” of the optical center mandates that it should be placed in front of the eye’s pupil. But often, regardless of total prescription power, that same OC is left to hang at a default position at the frame’s mechanical center, without consideration for the pantoscopic tilt of the frame front and its important role in positioning a lens correctly using corrected curve theory. Perhaps surprisingly, both situations are technically wrong: In the first case, it is the abbe or dispersive power of the lens material that is incorrectly prioritized and in the second, not specifying a vertical placement for the optical center reveals how broadly the fitting of corrected curve lenses is not fully understood.

THE POWER OF ABBE

The effect that the Abbe of a lens material has on the perceived optical performance of the wearer is related to:

- The actual dispersion of the material, which is inversely related to the Abbe number.

- The refractive power of the Rx at the chosen gaze point.

- The distance from the optical center to where the line of sight intersects the lens.

THE POWER OF CORRECTED CURVE

In the first decades of the 20th century, lens companies began researching ways of reducing the cost of manufacturing custom prescription lenses while maintaining the custom Rx’s visual clarity across the eye’s field of view. Previously, ophthalmic lenses with this level of performance required individual calculation of front and rear curves for each individual Rx, a time-consuming and expensive way to produce lenses. When the idea was presented of grouping nearby corrections onto a common curve and allowing very small amounts of peripheral aberration to be present, we entered the golden age of corrected curve lens design. In the 1920s and 1930s, when frame choice dictated fitting “on PD and pupil height,” little additional measuring was needed to assure wearers the finest optical performance. But in the 1940s, as frame fashion evolved with larger and less symmetrical shapes, corrected curve lenses often required decentering of the optical center—vertically as well as horizontally—from the frame’s mechanical center, the need for additional fitting measurements became clearly important.

THE POWER OF FRAME SHAPE

As frame shapes deepened and widened, opticians and optometrists had to pay attention to the vertical position of wearer’s pupil and adjust the optical center in accordance with Martin’s Rule of Tilt—which specifies lowering the OC 0.5 mm for every degree of pantoscopic angle—in order to properly align the lens’ image shell with the eye’s far point sphere. This metric assured clear vision in all the expected gaze angles. Now fast forward to the 1970s and 1980s, with more dispersive lens materials entering the market and frame shapes growing to disproportionately large sizes, ECPs were now challenged with trying to balance delivering the best vision through proper OC placement while assuring acceptable cosmetics. And this is when the first skirmishes in the war between eyewear optics and cosmetics broke out. Even today, the importance of using the actual frame shape for optimizing both optics and thickness with free-form lenses cannot be overstated.

THE WAR BETWEEN OPTICS AND COSMETICS

In the late 1970s, as frame styling reached super-sized proportions, maintaining compliance with corrective curve theory resulted in finished lenses having steep curves, thick edges and wedge-like profiles. In order to deliver better cosmetics, opticians began to abandon complying with corrected curve theory and sought out lenses made from a new, thinner, lighter and flatter-curve lens material called polycarbonate. But despite these attractive qualities, polycarbonate lenses had one real drawback: They were highly dispersive, having a low Abbe number of 30, which compared poorly to traditional lenses made from glass or standard 1.50-index plastic having an Abbe value of 58. And so opticians found themselves in a war that continues to this day, having to choose between delivering the best optics versus the best cosmetics.

THE RISE OF THE OC

As more and more opticians paid less and less attention to fitting lenses in a manner compliant with corrected curve theory, and with polycarbonate lenses increasing in popularity, a sort of perfect storm occurred: Patients began to complain of both reduced central acuity and poor peripheral acuity, both of which were due to polycarbonate’s low Abbe and the use of flatter lens forms than corrected curve theory required. Opticians responded by reducing the distance between the wearer’s pupil and the lens’ optical center in an effort to help restore central acuity. Over the years, this new priority became codified in the oft heard phrase “Be sure to take an OC height.”

Unfortunately, thinking of the OC this way could not be farther from the technically correct truth. Today, whether fitting aspherics or advanced free-form lenses, what is commonly called the “OC height” is really one of the cardinal points of eyewear fitting that should be more correctly called the pupil height. Then, depending on the specific type of lens design chosen, the pupil height becomes the basis for calculating the fitting height ordered from the lab. The final placement of the actual optical center is then dependent on the type or manufacturer of the lens design chosen.

BEYOND PD AND PUPIL HEIGHT

Until the arrival of customized free-form lenses, the most advanced measurement an optician would take would arguably be vertex distance, which is the linear separation of rear of the eyeglass lens from the corneal apex. For almost 100 years, vertex distance was a value viewed as being required only for prescriptions higher than 6 diopters. It was solely used to adjust the power of the lens ordered when the distances varied between the refraction and the fitted eyewear varied 1 to 2 millimeters or more. Note: This “power compensation,” seen from the lens designer’s perspective, is nothing more than aligning Rx lens’ image shell to the uncorrected eye’s far point sphere.

Today, advanced free-form design lenses allow for the integration of personalized fitting values for frame tilt, wrap and vertex distance in addition to the traditional measurements of PD and pupil height. Instead of using the aggregated average represented by default fitting values, optimizing a lens through personalized measurements represents the gold tandard for optimal alignment of the lens’ image shell to the eye’s far point sphere, making these the finest ophthalmic lenses ever available. Let’s take a quick look at each one of these personalized measurements:

- Vertex Distance: As noted above, traditionally associated with power adjustments in Rxs over 6 diopters. But as employed in a free-form compensated lens design, the fitted vertex value really represents three things:

- Proper alignment of the lens’ image shell across the ametropic eye’s far point sphere.

- By better approximating where the eye’s gaze angles intersects the lens surface, vertex distance values help determine which areas of the lens surface should receive more consideration, called merit weighting, within the optimization process.

- Along with the distance and near PDs, pantoscopic tilt, frame shape and the given Rx, vertex distance can help to determine the best corridor length in a variable progressive corridor design.

- Frame Wrap Angle: Only within the last 20 years has measuring frame wrap angle come into vogue. Before that, lens designers assumed that the frame wrap angle would rarely lie outside of the nominal 0 to 5 degree range. But driven by the desire for prescription sport eyewear, wrap angle has become one of the most important of the advanced measurements in free-form lens optimization.

- Pantoscopic Tilt: This is the actual vertical tilt of the frame/lens plane in front of the expected distance gaze, or line of sight. Exclusive to this measurement is the importance of how wearer posture can impact the final tilt value. It is essential that every eyecare professional retain a keen awareness of the influence of wearer posture on this value and constantly seek to ascertain the patient’s natural, normal and representative posture.

MEASURING FOR BIFOCALS

Perhaps in no area of eyeglass measurements do ECPs who otherwise pride themselves on their measuring skills abandon any presumption of precision or accuracy than when they’re preparing a work order for segmented lenses like bifocals and trifocals. First of all, the traditional wisdom is to set the height of bifocals “at the lower lid.” But when you stop and think about it, is there any less precise a reference than using a patient’s lower lid? Individual variations in lid aperture and head posture will dramatically affect the position of the lower lid in relation to the pupil. A better metric would be to return to the idea of simply taking a standard pupil height measurement and then determining how far below the pupil the segment line should be set. Below is a range of suggested values:

- Flat-Top Bifocals: Set up between 8 mm and 10 mm below the pupil. If you find the patient is wearing their present segments higher than 8 mm or lower than 10 mm, be ready to query them on overall comfort and utility with their current position.

- Flat-Top Trifocals: Set them between 3 mm and 5 mm below the pupil. Same advice applies to positions found outside this range.

- Round Segment Bifocals: Set them between 7 mm and 9 mm below pupil because of their reduced segment lines.

THE PARADOX OF BIFOCAL PRECISION

Besides the imprecision of using the lower lid to set the segment height, opticians further abandon accuracy in bifocal/trifocal fitting by ignoring the use of monocular PD and height values, bowing to the cosmetic symmetry of using a binocular PD and symmetrical heights. The reasoning behind these choices is a clear example of the ongoing war between optics and cosmetics: Symmetrically placed segments not only look good, they work primarily because their larger reading areas forgive lack of monocular placement, unlike progressives, without impacting near utility.

It is also interesting to note that even when opticians correctly calculate a corrective curve compliant OC position in single vision lenses, they often allow the lab to default OC placement to the frame’s mechanical center in an order for bifocals, neglecting all the accuracy they might otherwise prioritize in a single vision pair. Go figure.

THE FUTURE OF EYEWEAR METRICS

Today, the measuring equipment found in most optician’s toolboxes ranges from the lowly pen and ruler to the tried and true pupilometer, all the way to the latest in sophisticated digital centration devices. Any of these tools, in the hands of an experienced and trained optician, helps them to deliver the finest eyewear made. But of late, the pen and ruler have come under assault, being looked down upon as old school and lacking in sophistication. But if they were inherently obsolete, opticians wouldn’t continue to rely on them as their preferred go-to tools when challenged to troubleshoot an unsatisfactory pair. With technology never relinquishing its forward march, perhaps its ultimate impact on the art of producing fine eyewear will be by making the measuring process far more democratic, thereby freeing it from need for expert oversight by an experienced eyecare professional. As recent technologies such as 3D scanning of facial features and the use of in-home frame templates are increasingly employed to determine an even more advanced set of eyewear fitting measurements, it’s not impossible to imagine the idea that recording a person’s average head posture could soon become the norm. The primary job of an optician may evolve to become more of a supervisory role, charged with assisting with the total dispensing experience... an experience increasingly self-determined by the eyewear consumer of the 21st century. ■

A BRIEF ROUNDUP OF DIGITAL MEASURING DEVICES

AUTOMEYES

A measuring app that employs your phone, tablet or digital camera to quickly and easily determine PD, height and more. Automeyes’ mission for their app is for it to be amongst the very easiest tools for any experience level optician to use.

automeyes.com

ESSILOR VISIOOFFICE 2

The latest generation in floor-standing digital centration devices, the VisioOffice 2 measures eye dominance, head cape and eye-to-head turn ratio, in addition to PD, height and the full suite of position of wear measurements to bring a single measuring solution to every optical office.

essilorusa.com

HOYA SPECTANGLEPRO

The latest version of SpectanglePro takes the full suite of basic and advanced eyewear measurements. In addition, SpectanglePro allows specification of lens base curve and features a “comfort-height” option that auto-calculates OC position based on measured pupil height and pantoscopic frame tilt.

thehoyafreeformcompany.com

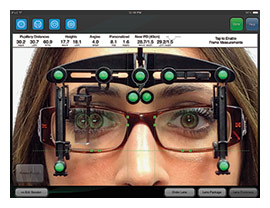

OPTIKAM APP

OPTIKAM APP

The OptikamApp is the latest version of a comprehensive measuring app that delivers the full suite of eyeglass measurements, including all position of wear values. Unique to the OptiKamApp is the E-Y reference device which quickly determines and locks in a wearer’s natural posture, thereby freeing the operator from the need to ensure precise camera alignment when taking the “money” shot.

optikam.com

SHAMIR SPARK MI

Masquerading as a typical desktop dispensing mirror, the new Shamir Spark Mi quickly obtains all the important measurements with the touch of a button. Unique to the Spark Mi is its capability to take measurements even through tinted or sunglass lenses.

shamirlens.com

ZEISS ITERMINAL 2

A fully outfitted tabletop or floor standing digital central device that takes accurate PDs, heights along with pantoscopic tilt, vertex distance and frame wrap angle. Easy to integrate in a full office system including Zeiss iScription.

zeiss.com

Contributing editor Barry Santini is a New York State licensed optician based in Seaford, N.Y.