By Barry Santini

The eyewear consumer is smart and well informed. The internet has seen to that. They arrive at your shop with a wealth of knowledge and more often than not are ready to consummate a purchase. But today they may also have a frame in hand they’ve purchased elsewhere... online, outlet or wherever. Instead of starting off on the wrong foot by insisting on a waiver of responsibility, why not take the order with a smile, without the expectation something may go wrong? It’s time to move beyond the send-the-job-to-the-lab mindset and put the power of in-office finishing to work in your place of business. By doing so, you’ll move into a position of advantage in an ever more disrupted eyewear market, one where consumers willingly pay extra for convenience and really want to become your client and not one of an anonymous online entity.

A well-equipped in-office lab can give you a competitive edge when it comes to service

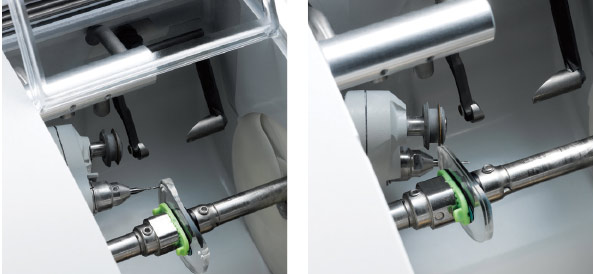

ENTER THE IN-OFFICE EDGING SYSTEM

The latest computerized edging systems are perfect for delivering fast quality lens preparation. They’re quiet, competent and versatile systems that make the average optician look like a rock star! In the hands of an experienced one, they soon become renowned for their “mad” edging skills. The advantage of being able to offer while-u-wait service and prep-to-your-own frame cannot be understated today. Nothing stops a shopper ready to walk out with their Rx faster than saying, “Would you like to have your new glasses in the next 30 minutes?”

IT’S NOT JUST ABOUT SAVING MONEY

It’s about saving time. And time is precious—for both optical and consumer. Then there’s also the lure of instant gratification—having your new eyewear right now, instead of waiting even one more day. Can’t routinely be done in 30 minutes you say? Think again. Auto-lensmeter reading blockers and optimized 3D beveling means you simply clean the lens, block it, place it in the edger and engage AUTO mode. Voila! It is done.

Further, many consumers want to put lenses in their own frame but conclude that they can’t be without them and therefore have to purchase new. Today, in-office finishing makes this possible using the latest memory features. (See Sidebar: “Mastering the Machine.”) By being willing to adjust to current consumer demand when other businesses don’t directly translates into building a trustful relationship with your clients.

START WITH THE POWER OF PLANO

As previously mentioned, optical consumers today are well informed. They are knowledgeable about the importance of managing their UV, blue light and blinding glare exposures. And even if they are not wearing a prescription—especially if they’re not wearing a prescription—people are receptive to listening about upgrading their plano sunwear. Not a week goes by in my office where I don’t get an inquiry about plano blue light filtering eyewear or how updated LED office lighting is negatively impacting their visual comfort and safety. There are millions of plano sunglasses that can be upgraded to better filtering, glare reduction or even color enhancement. Why send these easy to do in-office orders to an outside lab, with all its attendant risks, costs and potential delays? If you’re adventurous, try your hand updating OTC readers to better-than-acrylic lenses or even to a proper binocular-optimized Rx. Today, there are OTC reader frames equal to the quality seen in many branded products. Do not be afraid to hang a sign heralding “We welcome your frame for new lenses.” Remember: Convenience is a premium people will pay for.

Today’s patients like the convenience of same-day service, which an in-office lab can provide

SMART EYEWEAR: WHO ARE THEY GONNA CALL?

Apple, Google, Facebook and others are about to enter the smart eyewear segment in a big way. This means lots of residents local to your store will be searching for a nearby optical willing to place their Rx in these new technology frames. And if no one nearby will do it, they’ll travel. Can you say opportunity? Having an in-office lab helps you make this happen, but only if you are receptive to, comfortable with and experienced in handling orders using frames purchased outside your store. Traditionally, optical frowned on or discouraged the glazing of outside frames, preferring to always supply new or keep the buying process all under one roof. But fragmentation is going to become a large part of optical’s future. Stake out your claim in this frontier market by instructing your webmaster to search engine optimized phrases like “lenses to my own frame near me.” You’ll see a whole new class of cash buyers who don’t need discounts or incentives to Rx their smart technology eyewear.

People are impressed when you say “Yes” when others say “No.” The benefits of being willing to handle outside Rx and eyewear drops directly to the bottom line, improving your all-important bona fides and buyer satisfaction.

WINNING THE OPTICAL CONSUMER

Winning the optical consumer in the 21st century is all about understanding how much things have changed yet remained the same. There are still the same fundamentals based on service, but the opportunities to service have changed. It’s no longer strictly about after sales for a purchase made in your store. It’s about recognizing that being a brick-and-mortar optical in your local community brings with it advantages that no Amazon-sized online behemoth can conveniently bring to the table. When the ever more fragmented optical consumer has a service need, it’s time to be willing to pick up the pieces. Baby steps are the path to re-establishing your store as one today’s optical consumer feels they can trust and turn to for help. And they will repay that trust in kind. There’s something very special in a direct, face-to-face, hands-on transaction. And no online entity will ever usurp the primacy of this fundamental human need. ■

MASTERING THE MACHINE

Most edging system proposals are presented with an ROI (return on investment) scenario. Business owners then trot out all the excuses as to why they don’t need it, why it’s too expensive or why there aren’t enough skilled opticians or staff around to make it work. But today, edging technology has dramatically reduced the need for a dedicated highly skilled bench tech. And sure, even the person answering the phone can be taught to fixture a lens and push the start button. Using this as a criterion, edging system sales should be plateauing. And they are. Why? Because there’s more to leveraging an in-office finishing system than glazing new eyewear. There’s a service angle, outlined above, being overlooked in just about every edger proposal. Let’s take a deeper dive on how in-office edging expands your service offering.

EYEGLASS WEARER IN TROUBLE!

When a prescription frame breaks, it is always a disaster for the wearer. Most frames cannot be repaired easily while someone waits, so remounting their lenses becomes the next best option. But unless the transfer is a “snap” fit, there will no doubt need to be some trimming of the present lenses to fit a new frame. With hand stones and hand edging certain to become a lost art, often the only way to fit present lenses to a new frame is to plop them in the edger and grind them down. But what if the edger’s lens mappers won’t trace the present lens fully so the grinding cycle will commence? The answer to solving this Rx problem is one word: plano!

PLANO TO THE RESCUE

The secret to re-cutting the patient’s own Rx lenses to a new frame when they won’t trace out is to have on hand a supply of standard plastic and polycarbonate planos in various base curves, i.e., 3, 4, 6 and 8 base. Nothing fancy needed: No AR, just find the cheapest lenses that fit the base curve criteria above.

Choose a replacement frame that is acceptable to the fit, cosmetics and budget of the person in crisis. Start by measuring the DBL of the broken frame. Make sure the replacement frame’s DBL is within 1.5 mm of the original frames. This will ensure acceptable final centration for even finicky progressive wearers. Block the Rx lenses, taking care to center properly. Now block a plano lens of the same material and base curve (within 1 diopter is perfectly fine). Now cut the planos using the traced shape of the replacement frame. Set the edger bevel to FRONT, meaning to follow the base curve. Set the size large, say +0.4 mm to 0.5 mm large. Finish the plano lens, no safety bevel needed. Next, put the Rx lens in and retouch at the same size. This cycle time should be short. Test fit the Rx lens to the new frame. Decrease set size by 0.15 mm for each subsequent retouch. Eventually the lens will snap into the new frame, and you are done with the right lens. Repeat for the left, making sure you initially start large again.

When you’re done, say 15 minutes tops, you’ll have a customer for life. How many stores will entertain this recut procedure? Not many. Can you say opportunity?

—BS

Contributing editor Barry Santini is a New York State licensed optician and contact lens fitter with Long Island Opticians in Seaford, N.Y.