By Tina Lahti, ABOC

What is “the drop” in a progressive lens, and what, if anything, does the drop indicate about the design?

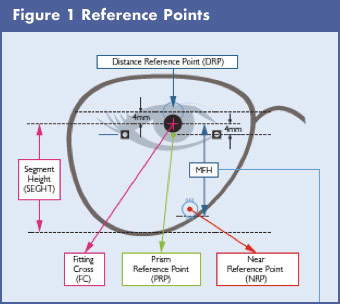

To define the drop, we must first have a working definition of the Prism Reference Point or PRP. The PRP is a control point in a progressive lens used to verify thickness, prism and mounting. This reference point is required by ANSI and used to verify the accurate manufacture of a completed pair of prescription eyeglasses. The lenses typically arrive with the supplier’s layout chart and is generally used to find the PRP. It is depicted as a dot, generally a short distance (2 to 4 millimeters) below the fitting cross. When lenses are marked for verification and placed on the wearer, the PRP should be in line with the wearer’s pupil vertically (see Fig. 1) and is generally, but not always, a short distance below it horizontally.

Drop is a term used to define the vertical distance in millimeters from the fitting cross to the PRP. This distance is not an industry standard. It can vary by supplier and by design. The drop of a lens is commonly 2 or 4 millimeters but can be whatever the designer decides based on where they think prism should be verified. Lens designs are available with a drop of 2, 3, 4 and even 0.

Opticians who fit PAL lenses rely on their suppliers to utilize a standardized layout that is based on engravings set 34 mm apart along a straight horizontal line, the center point on the lens between the engravings is the prism reference point. This line is commonly referred to as the 180-degree axis, an indication that it is perfectly horizontal. Once an optician locates the PRP reference point, they need only know the drop of the lens to determine how many millimeters above the PRP the fitting cross is located. With this information and the manufacturer’s centration chart, they can find the general location of the distance (DRP) and near (NRP) reference points relative to the wearer’s pupil. These reference points are where power is to be measured upon final inspection.

It may come as a surprise to many opticians to learn that the drop of a lens is not related to the specific placement of power within a lens design. There is a common belief that add power begins to build at the prism reference point and that unwanted spherical and cylinder power in the periphery is concentrated below the 180-degree axis. This simply isn’t true. The power distribution and location of unwanted cylinder power are not directly related. The designer determined the location when inspecting for prism verification and center thickness.

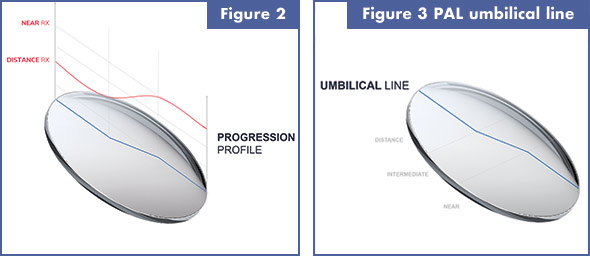

The slope or rate of increase of power within a progressive lens is referred to as the progressive profile or power profile. This slope can be fast or slow and can have flatter and steeper sections. It can begin at any point below or even above, as is the case for office lenses, the fitting cross. (See Fig. 2)

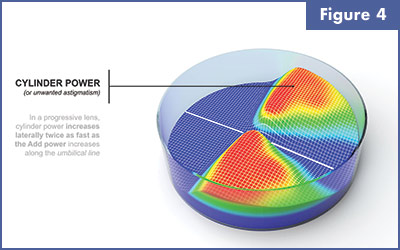

The slope follows along a line referred to as the umbilical (Fig.3). Think of this as the spine or backbone of a progressive lens that travels through the central part of the body from the distance reference point (DRP) to the near reference point (NRP). Starting at the center of the line and moving laterally to each side is the necessary unwanted cylinder power that we call distortion and wearers perceive as visual swim. (See Fig.4)

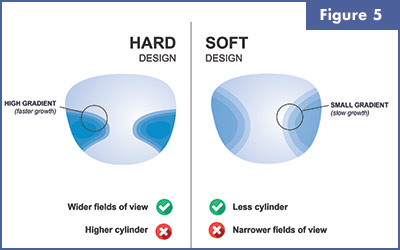

This can be concentrated into a relatively small portion of the lens; we call this a hard design. Or

it can spread out as to create a soft design. Each design decision has benefits and necessary trade-offs, but none are directly linked to the distance between the PRP and fitting cross, aka the drop.

These two elements, progressive profile and hardness or softness (Fig. 5), are determined by designers based on the intended visual use of a specific design. For example, a design created for optimum distance vision may be very hard with unwanted cylinder power only in a small area well below the180-degree axis. A lens design created for use with mobile devices might have a progression profile that builds quickly in the upper portion of the lens and more slowly toward the bottom. Both lenses described above could easily have the same drop.

The drop of a progressive lens is not in and of itself a design element, and it is not directly related to either the progressive profile or placement of unwanted cylinder power. It is, quite simply, the lens designer’s chosen placement for the prism reference point in relation to the fitting cross.