By Linda Conlin, Pro to Pro Managing Editor

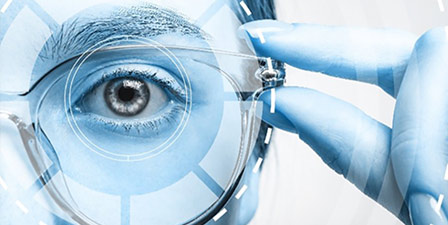

Smart contact lenses are high-tech contact lenses capable of displaying visible information on our corneas and can be used to access augmented reality. While eye care professionals and consumers have been anticipating commercial availability of these lenses, developers have met with setbacks. The lenses need to be powered by rechargeable batteries that rely on wires or induction coils that contain metal, and so present risks to the wearer. Now, scientists from Nanyang Technological University, Singapore (NTU Singapore) have developed a flexible battery as thin as a human cornea, that stores electricity when it is immersed in saline solution, and which could one day power smart contact lenses. (Nanyang Technological University. "Scientists invent micrometers-thin battery charged by saline solution that could power smart contact lenses." ScienceDaily.)

The NTU-developed battery is made of biocompatible materials and does not contain wires or toxic heavy metals, such as those in lithium-ion batteries or wireless charging systems. It has a glucose-based coating that reacts with the sodium and chloride ions in the saline solution surrounding it, while the water the battery contains serves as the 'wire' or 'circuitry' for electricity to be generated. The battery could also be powered by human tears as they contain sodium and potassium ions. During non-wearing periods, as at night, a battery combined with a biofuel cell could charge while in a contact lens case filled with a highly concentrated biofuel solution. Additionally, the battery can be charged conventionally by an external power supply. Sodium ion batteries were developed in the 1970s, and consist of a cathode based on a sodium-containing material, an anode, and a liquid electrolyte. During charging, sodium ions move from the cathode to the anode while electrons travel through the external circuit. During discharge, the reverse process occurs.

Among the challenges to smart contact lens development has been the size and thickness of the base lens itself. To integrate various functions into smart contact lenses, all components need to be miniaturized, while adding minimal thickness to the lens. The lens must also be flexible, able to bear the pressure of blinking, and the components can’t interfere with vision. In this lens, the electrodes were placed at the periphery of the contact lens, and vision was not obstructed. The miniaturization of the electrical parts allowed enough space for integrating the electronics and sensors with the battery, while the increase in thickness approximates that of the cornea. Additionally, the contact lens was sturdy enough to withstand folding.

The team demonstrated their invention using a simulated human eye. The battery, which is about 0.5 millimeters thin generates electrical power by reacting with the basal tears that create a constant film over the eyeball. Although not yet tried on humans, the NTU team has filed for a patent, and will be conducting further research. They also will be working with several contact lens companies to implement their technology.